The company currently operates 11 waste-to-energy plants across Punjab, Haryana, and Rajasthan, with a combined capacity of 165 MW.

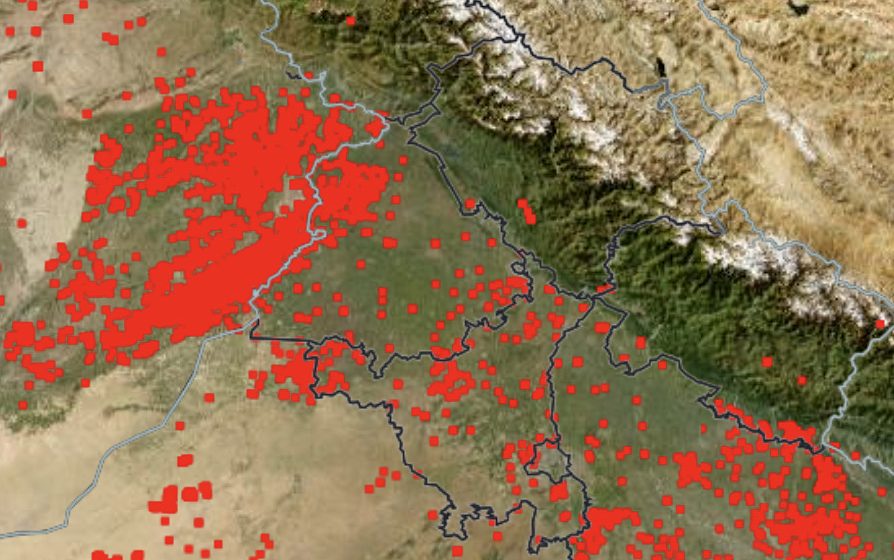

SAEL Industries Ltd, an integrated renewable energy company, has announced plans to procure nearly 2 million tonnes (MT) of paddy stubble this harvesting season through its fuel aggregator network. The biomass will be used to power its waste-to-energy (WTE) plants across northern India, in a bid to curb stubble burning and convert agricultural residue into clean electricity.

SAEL currently operates 11 WTE plants across Punjab, Haryana, and Rajasthan, with a combined capacity of 165 MW. An additional project is under construction in Rajasthan.

According to the Indian Journal of Agronomy, India generates approximately 500 MT of crop residue annually, of which nearly 140 MT remain unutilised. Over 90 MT is burnt in open fields, contributing significantly to air pollution and public health risks across northern states.

SAEL’s procurement drive aligns with estimates from the Intergovernmental Panel on Climate Change (IPCC) guidelines for national greenhouse gas inventories (2006), which suggest that diverting crop residue from open burning could help avoid nearly 300,000 tonnes of carbon dioxide-equivalent (CO₂e) emissions.

“Crop residue represents an underutilised opportunity, environmentally, socially, and economically,” said Laxit Awla, CEO & Executive Director, SAEL Industries. “By converting agricultural waste into clean energy, we are not only creating new income avenues for farmers but also tackling the issue of stubble burning. This initiative helps preserve soil health, reduce emissions, and strengthen India’s energy resilience.”

SAEL’s CY2024 Greenhouse Gas (GHG) Report indicates that its WTE operations have already achieved avoidance of 390,859 tonnes of CO₂e emissions. The company has also set up fuel collection centres across villages, employing local workers and building a decentralised supply chain for biomass aggregation.