From cost overruns and procedural hurdles to technology-driven savings and timely execution, Bharatmala Pariyojana demonstrates how adaptive infrastructure ensures efficiency and future readiness, explains Shailesh Agarwal.

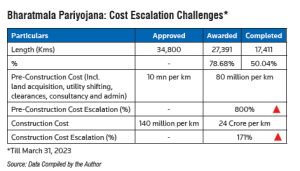

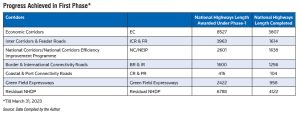

The Bharatmala Pariyojana, launched in 2017, was conceptualised as a nationwide highway development initiative to optimise freight and passenger movement. In its first phase, the programme aimed to develop 34,800 km of national highways with a financial outlay of Rs.5.35 trillion by September 2022, per the Comptroller and Auditor General’s (CAG) annual report, with implementation progressing in phases across various regions.

Hitting roadblocks

Challenges started appearing once the project rollout began in the right earnest. The initially approved target length of 24,800 km was later increased to 34,800 km, a 160 per cent rise post-optimisation. However, this expansion was carried out without corresponding financial approvals, resulting in a gap between the revised targets and available resources.

Despite the Cabinet Committee on Economic Affairs’ (CCEA) mandate, several projects were awarded without securing 80-90 per cent of the right of way (RoW). Consequently, projects such as Barhi-Koderma and Chordaha-Gorhar suffered multi-year delays due to pending forest clearances and land acquisition disputes.

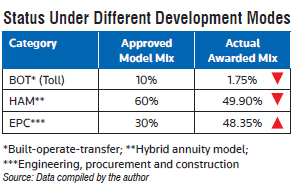

The skew towards engineering, the procurement and construction (EPC) model increased the fiscal burden on the government and reduced private sector risk sharing. Detailed Project Reports (DPRs) lacked site-specific feasibility alignment and were often prepared without adequate traffic studies or stakeholder consultation.

Issues concerning fund utilisation and borrowing oversight also cropped up. The National Highways Authority of India’s (NHAI) cumulative borrowings stood at Rs.3.00 trillion against Rs.2.09 trillion approved for Bharatmala as a whole. The financial outlay of Rs.10.55 trillion projected by NHAI for 2019 was almost double the original allocation.

Technology in various forms, i.e., artificial intelligence (AI), internet of things (IoT), drones, robotics and other digital initiatives, is reshaping how highways can be planned, built and maintained. Before delving deeper into how technology can be an enabler, its key areas are summarised in the table below.

AI-based route modelling

One of the most transformative applications of AI in highway development lies in route optimisation. Using AI-powered modelling, satellite imagery, and geospatial analytics, planners can determine the most feasible highway alignments. These tools factor in terrain, population density, environmental sensitivity, and infrastructure constraints, thereby minimising land acquisition hurdles, costs, and ecological disruption.

It is estimated that the Delhi-Mumbai Expressway, India’s longest expressway at 1,386 km, where AI-based geospatial modelling helped authorities reduce land acquisition by nearly 15 per cent, translating to estimated savings of over Rs.100 billion. Furthermore, the AI-optimised alignment supported the inclusion of over 70 wildlife crossings, including animal underpasses and India’s first dedicated wildlife overpass, enhancing ecological connectivity without compromising infrastructure goals.

Internationally, the Stockholm Bypass (Förbifart Stockholm) in Sweden—a 21-km expressway with 18 km of tunnels—used machine learning and building information modelling (BIM) to simulate over 50 alignment options. This approach enabled planners to select a route that not only reduced environmental disruption but also cut projected costs by SEK3 billion (around Rs.240 billion) in a project budgeted at SEK37 billion (Rs.295 billion).

IoT in construction

The deployment of IoT-enabled sensors across project sites has revolutionised project construction. These sensors track parameters such as material quality, temperature, and stress levels. When integrated with AI-based image recognition systems, engineers can monitor structural health, construction quality in real time and take corrective actions.

The Automated Intelligent Machine-aided Construction (AIMC) initiative by the Ministry of Road Transport and Highways (MoRTH) redefines highway construction by integrating automated machinery, GPS-based controls,

and real-time digital monitoring through certain key technologies.

Utilising 3D machine-guided graders for precision earthwork ensures accurate cutting and filling operations, leading to optimal subgrade preparation. Traditional paving uses physical stringlines to guide equipment, often leading to delays and human error. Stringless technology replaces these with GPS and robotic total stations, enabling precise control of paver alignment and elevation. This improves surface smoothness, cuts setup time, and reduces manual errors.

Similarly, IoT-enabled systems feed live data to cloud dashboards for transparent monitoring. A standout feature is intelligent compaction (IC), using GPS-equipped rollers with onboard sensors to track pass count, stiffness (CMV), amplitude, and frequency across the entire compacted area, far beyond traditional point testing. This ensures uniform density, reduces post-construction defects, and enhances pavement life. This results in faster, high-precision execution with minimal or almost no rework, real-time quality control and documentation, greater durability, improved ride quality, and reduced manual errors and enhanced productivity.

Piloted successfully on the Lucknow-Kanpur Expressway, AIMC is now being scaled across select expressway and greenfield projects, supporting India’s vision of advanced highways by 2047.

Telangana’s Hyderabad Outer Ring Road is a prime example, equipped with IoT-enabled smart poles that monitor environmental conditions, structural strain, and traffic density, contributing to data-driven infrastructure management. The system has already helped substantially reduce traffic incident response time, notably by 30 per cent, and is integral to the city’s broader smart mobility initiatives.

One of the most prominent global examples is Australia’s WestConnex project, where IoT systems are embedded across tunnels and bridges. The sensors stream real-time data on stress levels and material fatigue to an AI-integrated dashboard for predictive maintenance. The WestConnex Maintenance Dashboard has been credited with cutting down reactive maintenance needs by up to 25 per cent since its deployment.

Drone deployment

To accelerate project timelines and improve execution precision, drones are being widely adopted. From earthmoving and grading to paving and structural inspections, these intelligent systems are enhancing the quality of construction and timeliness.

As part of our ongoing efforts for EPC contractor under Bharatmala Pariyojana for the Unnao-Lalganj section of NH 31, we conducted drone-based inspections across sample stretches to assess both centreline alignment and cross-section accuracy of the main carriageway. High-resolution aerial mapping revealed deviations in centreline positioning, enabling timely corrective measures. Additionally, drone-captured cross-section analysis identified issues such as excess shoulder work and reverse slope, particularly between chainages. These insights have proven valuable in minimising rework, enhancing accuracy, improving compliance with design specifications, and ensuring higher construction quality under Bharatmala.

India’s Dwarka Expressway is a strong domestic example. The project deployed automated construction technologies

and drones to monitor execution quality and ensure efficient resource management, streamlining the timeline and reducing human error. According to NHAI reports, this technology-led monitoring resulted in a

10-15 per cent reduction in project delays and significantly improved material management efficiency, while also reducing on-ground human dependency.

A noteworthy international reference is Dubai’s Sheikh Zayed Corridor upgrade, which is part of the emirate’s smart roads initiative. Here, AI-powered drones and robots have reduced construction timelines by over 30 per cent while enhancing safety and data precision for remote monitoring.

Enhanced transparency

AI is also transforming supply chain management in highway construction. Predictive algorithms analyse historical usage patterns and project timelines to forecast material needs to prevent shortages and delays. In parallel, blockchain-based procurement represents a next-generation approach to infrastructure governance, where every transaction from tendering to delivery is recorded on an immutable digital ledger, ensuring transparent, traceable, and tamper-proof documentation.

A successful implementation of this approach can be seen in MoRTH’s Bharatmala Dashboard. The platform leverages AI and analytics to forecast material demand and monitor procurement efficiency, while integration with e-tendering platforms ensures contract transparency and reduces pilferage.

Smart highways, smarter maintenance

The future of road infrastructure is intelligent and responsive. AI-powered sensors embedded in highways can monitor parameters like vibration, stress, and temperature, allowing authorities to undertake predictive maintenance before problems escalate. This extends asset life and reduces operating costs.

This strategy has been effectively deployed in Bengaluru’s Satellite Town Ring Road (STRR), where embedded sensors are planned for real-time monitoring and integration with autonomous vehicle systems, enabling proactive maintenance and connected mobility. The system is expected to significantly improve response times to maintenance issues and reduce downtime by up to 30 per cent, based on projections from NHAI.

A compelling international application is Sweden’s E16 Electric Road, which uses AI-driven embedded sensors to analyse

wear patterns, facilitate real-time EV charging, and alert authorities to pre-emptive maintenance needs, demonstrating how highways can be both smart and sustainable. Per the Swedish Transport Administration, 2021 trials indicate that this setup could reduce EV charging-related downtime by 40 per cent and extend pavement life through precise, condition-based interventions.

Technology is no longer a support function—it is central to the future of India’s highway development. With AI-powered route planning, drone-based construction monitoring and IoT-driven asset tracking, the Bharatmala Pariyojana is steadily transforming into a smart, data-led infrastructure programme that truly epitomises innovation in motion. These innovations improve

efficiency, transparency, and long-term sustainability across the project lifecycle.

As India scales this initiative, the seamless integration of digital intelligence into every layer, from planning to maintenance,

will be key. The next chapter in highway development must not only focus on building more roads, but on building them smarter, faster, and greener—laying the foundation for truly intelligent, adaptive, and future-ready infrastructure.

About the author:

Shailesh Agarwal, Partner for Risk Consulting, EY India.

Ajay Jindal and Rishank Jha, Consultants, EY India, also contributed to the article.