Cement freight will now be charged at a flat rate of ₹0.90 per tonne per kilometre, based on actual distance covered.

Indian Railways, the world’s fourth‑largest rail transporter, has rationalised freight rates, introduced customised containers, and unveiled a new policy to establish bulk terminals for cement. The initiative is being viewed as part of the government’s broader effort to accelerate construction and infrastructure activity, with logistics reforms anticipated to reduce costs and enhance efficiency.

As the world’s second‑largest cement consumer, India produced about 426 million tonnes of the commodity in FY2023-24.

Following the announcement, Ashwini Vaishnaw, Minister for Railways, told mediapersons at Rail Bhavan in New Delhi, “This will reduce the cost of transportation, provide support to middle‑class families building homes in addition to the benefits extended under GST reforms, and will help considerably contain pollution while moving the commodity in new containers.”

With India emerging as the world’s second‑largest rail freight carrier, surpassing the US and Russia in FY2024-25 by transporting 1.6 billion tonnes of goods, this new rate structure for cement is an important step towards logistics reforms. Charges will now be based on actual tonnage, calculated as the gross tonne kilometre (GTKM) of the train. The earlier distance and weight slabs have been scrapped to enhance ease of doing business.

Under the revised framework, cement freight will be charged at a flat rate of ₹0.90 per tonne per kilometre for the actual distance covered.

Cleaner Logistics

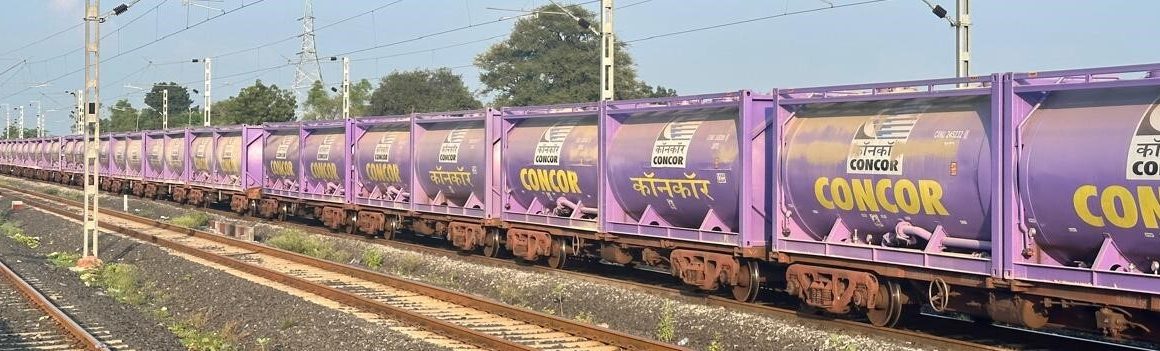

The public sector enterprise CONCOR has developed specialised end‑to‑end (E2E) tank containers to support efficient multimodal logistics for bulk cement. A ‘Make in India’ product, each container is built to ISO standards with dimensions of 20 ft × 8 ft × 8.5 ft, offering a payload capacity of 26 tonnes and a gross weight of 31 tonnes.

Each container allows efficient operations with loading and unloading times of just 25-30 minutes. Its design enables seamless multimodal transportation, moving easily from train to trailer and back, ensuring smooth delivery from production centres to consumption hubs.

Transporting bulk cement in specialised wagons is both cost‑effective and environmentally friendly. It reduces packaging requirements, minimises spillage losses, and supports sustainable logistics.

Bulk Cement Terminals

To further strengthen logistics, the Railways will facilitate the development of bulk cement terminals across the country under its new policy. These terminals will be constructed, operated, and maintained with direct connectivity to the railway network.

Facilities such as hoppers, silos, bagging plants, and related infrastructure will be integrated to ensure efficient handling, storage, and distribution of cement.

The policy promises several benefits, including reduced transportation costs, a smaller carbon footprint compared to road transport, faster turnaround times through mechanised loading and unloading, and reduced road congestion.

– Manish Pant